Concrete has been used in buildings of every scale since the Roman era, and it is difficult to imagine a structure that does not have at least one concrete feature. In reality, with high reliability, resilience, ease of handling, accessibility, aesthetics, and other qualities, it is the most commonly used construction material in the world.

At the same time, its production is a major polluter of the environment, owing to the fact that the cement sector accounts for approximately 8% of all worldwide carbon dioxide emissions (CO2).

In addition to its mass manufacture, concrete is a very strong, heavy substance made of cement, water, stone, and sand. So, would it be possible to use concrete in a sustainable manner after demolition, avoiding its disposal as garbage and overcrowding landfills?

The short answer is yes! Even if it isn't easy, it is possible to use concrete waste to make new structural parts while retaining basic properties of strength and resistance. To begin, it is important to recognize that the extraction of sand and gravel for tiny and big aggregates of concrete has a significant environmental impact, even when done locally.

Benefits of Concrete Recycling

When recycling something, you’ll definitely get a benefit as a renewed product and the same goes with the concrete. Aside from that, concrete recycling has many more benefits described below:

- Recycling concrete reduces building waste, extends landfill life, and saves builders’ disposal or tipping fees.

- It also saves money on transportation because concrete can typically be recycled near the demolition or building site.

- If a builder is pursuing LEED Green Building certification, using recycled concrete might earn them points.

- In certain cases, new job opportunities emerge as a result of a recycling activity that would not have existed otherwise.

- Recycling also reduces disposal costs while lowering the project's environmental impact.

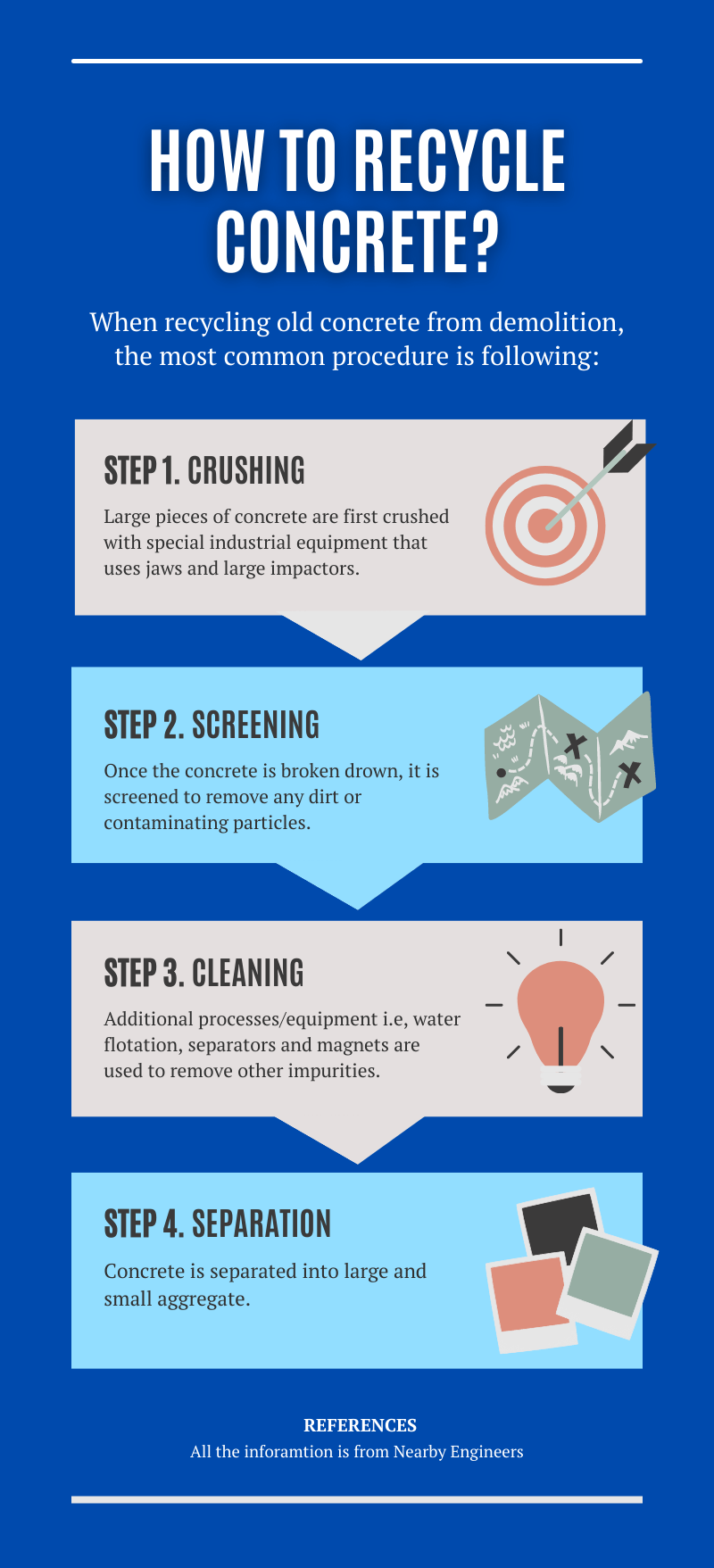

How to Recycle Concrete?

The particular method of recycling concrete will be dependent on the type and size of your concrete. This is often done by a construction materials business, which will either transport the material to a recycling facility or complete the procedure on-site with a mobile crusher operation.

So. let’s see how to recycle concrete with the help of an infographic below:

Equipment Used to Recycle Concrete

When considering concrete recycling as an option, you should also explore the choices for crushing the concrete. A portable crusher that can be relocated to multiple places or projects may be the most practical solution. It is often ideal to place a portable crusher in a central area, close to where the concrete is being demolished yet far enough away from site traffic.

Consider the following factors while selecting processing equipment:

- A strong magnetic, water flotation, or air separator device should be used to remove steel from concrete.

- The use of separate hydraulic stands will allow for a quicker setup.

- Automatic, manual, or remote control mechanisms are all possible.

- Conveyors, jaws, and cones-equipped systems can provide entire concrete processing, from demolition to usable material.

Final Thoughts

When compared to mining, manufacturing, and transporting new aggregates, reusing concrete saves a significant amount of energy. While not regarded as harmful to the environment, the vast quantity of concrete trash generated during deconstruction makes landfills hard to handle.

When it comes to sustainability, the most important thing is to comprehend the majority of the variables and aspects that influence the ultimate result. Many researchers are working to make concrete a more sustainable material.

New studies on the subject are being published on a daily basis, whether through recycling, sustainable mixtures of aggregates, or even processes that make the production of this material less damaging to the environment.